Hi folks

Thanks for your input. I will try to answer your questions about the plane and setup to make the picture clear.

The plane is a TopFlight Tutor which is a 45" plane, it is smaller than a regular .35-.40 plane and slightly bigger than a .25. My Aim for this was just to getting started and try out different combinations of motors, props and batteries. I also like to build as light as possible which explain my choices of motors.

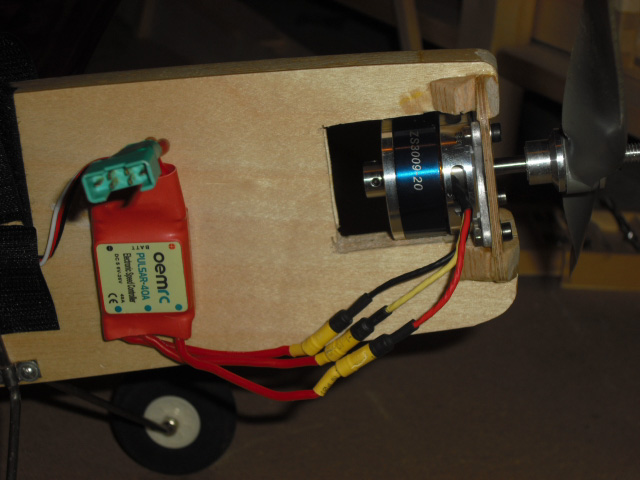

The motors have been front mounted as this makes it easier to change motor without significant changes in position and C.G.

I have so far been doing some testing with different props (9x4,5, 10x5, 11x5,5, 11x7 and 12x6) and it seams that a combination of pitch and rpm which gives a pitchspeed in the rage of 75-80km/h are good with my 17,5m lines (might be to long?)

Batteries are all 3s Lipol with 2000-2500mAh, they hold about 10-10,5V at a 25A load.

I have initially used an regular reciver with a transmitter on the ground, but the last weeks have a Will Hubin Timer which makes things easier.

The motors I have tested are:

- Turnigy C3536-1300rpm/V: I have run Turnigy for some years in RC and have never before had problem like this.

- Hyperion ZS 3003-1100 rpm/V, this motor are actually a little to low in the rpm/V number. I had to use high pitch props like the 11x7 to get this moving in the right speed.

The rpm has been in the range of 7500-9000 rpm and input power of 250W-280W, again 270W looks like a good number for this plane.

I can not see any problem to run out-runners at the weight of 100-125g with these numbers, I have RC-planes where I stress the motors significant more.

I guess I have to call out for warranty of the Hyperion (one week old) and figure out what to do next. I do have an Turnigy SK 3536-1450rpm/V with bigger bearings, this motor are in the high range of rpm/V, but a 12x4 might be a good choice? 12" are bigger than this plane was designed for, are there an upper limit of diameter or are bigger = better as in RC?

If I get things right are the next step to build a Brodak Vector .40 to build for next year.