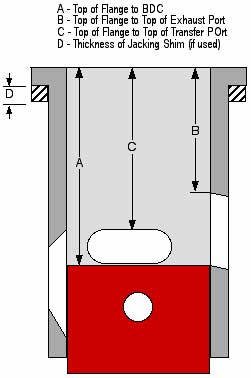

If you had a tooned pipe SPEED engine , youd raise the EXHAUST to increase the BLOWDOWN .

So THIS is what BLOWDOWN is . ( if He's got it right ) .

Cause He wants the NEGATIVE PRESSURE WAVE to Ram Charge the Cylinder , Which'll only happen if the Cylinders Shut , or it'd Blow Down the Trasfer Passage too . . .

But WE dont want to rev the Snot out of it , Ve Vant TOURQUE ! So George Aldrich said use 15 Degrees oor Less , Blowdown . To get the sucker to SWITCH 4-2-4 .

Which is the differance between B & C there , Rotationally tho .

The Higher the port top , the longer the ' period ' of course the longer the ' going around ' of the crankshaft ( Degrees ) for high speed snotters ,

with cranks closing around 60 degrees .

Where if ya wanna runin at say 8000 odd , about 45 crank closing, stops the intake eatlier , so ' it ' dosnt keep on going ' up there ' in rpms either .

Tho a lotta injuns , like the ST 46 , close lateish at 50+ degrees , so the crank timing dosnt seem as critical ,

Though some enormous cranks have enormous intake cut outs - so can flow twice as much as one half the size , in the same time .

EARLY Schnules , like the HP 40 , And Maybe your SPEED Webra ?? ( if its the round finned one ) Dont Have Huge Crank Passages ,

Or Huge TRANSFER PASSAGES or Huge Intake Cut Outs in the Sleeve , so there .

So one sticks a 360 degree Protactor , or if decadent , a Timing Disc , on the crank ( where the prop goes ) pulls the head off , sticks a poiter to a lug ,

turns things , uses a flashlite , and writes down when it all shuts and opens .

Then you can use tecnical terms like

I.O. = Inlet Opens .

I.C. = Inlet Closes

E.O. = Exhaust Opens

E.C. Exhaust Cl;oses

These are usually the same , on our two strokes , bar some clever sods offset the crank or cylider sideways .Say on the Fox 35 , Then They ARNT . The Same . Tho Similar .

Also A T D C = After Top Dead Center

A B D C = After Bottom Dead Centre

Which is where the sleeve ports is open . Ea Side of B D C , so Ea Side Added ( say 70 ) = Twice As Much ( say 140 ) ( Degrees , a fairly usefull Exhaust Period

- 15 twice gives 110 MAXIMUM on the Trans , or it wont 4-2-4 , it wont back off once it got up , in rpms . So I suppose it acts like a choke. The Blowdown .

Either thats a revelation or theres some other explanation .

Actually 130 Exhaust Duration is pretty good , the Early HP 40s go down there with the liner dropped about 30 thou . And 110 Inlet .

Anything over about 145 Exhaust , which'd mean minimum 115 Inlet ( on the sleeve ) preferably 10 blowdown so 125 . ( Maybe less blowdown as the RPM range is Raised ??)

isthe dreaded ?? 4 in pitch range , in the So Called SCHNEURLE engines .

The Sleeve Timing for a BAFFLED PISTON ENGINE is wilder than oon a Flat Top Piston - Multi Port . Perhaps .

ANYWAY , Raiseing the TOP of the TRANSFER PORT , ( un piped ) is to REDUCE THE BLOWDOWN . ( Dropping the Sleeve is to Narrow the Timing to Reduce the RPMS at Maximum effective TOURQUE ,

So its ' on the Hump ' in the power band , the ' sweet spot ' where its happiest sitting .