And now with the picture

I'd give it a solid

B. The bends could be smoother, and you've still got a flex point between the copper wrap and the tubing bushing. I'd also throw a washer on the bolt through the ball link, or flip the bolt over so the link can't pop off, but that's probably just a bit of healthy paranoia. It'll probably work fine, assuming it's free to move smoothly. If it sticks anywhere or has tension anywhere in the arc of motion, fix it.

Generally, I solder washers to the bellcrank post to center the bellcrank, and keep it from tilting, then after the plywood reinforcement is added top and bottom, I solder another washer to the post outside the plywood to keep the post centered in the wing. That way no spacers are necessary. This assumes you are on good terms with your soldering iron.

Andrew,

You're really knocking the product.

Perfect bellcranks were undergoing pull tests long before you were involved in modeling. The bellcrank in the top photo is older than you are. So is the wing.

Similar ones are currently being offered by Fox. I use Fox bellcranks.

Mine is doubled.

The model will come apart before the bellcrank bends.

And as long as it operates smoothly, it can be used in any model.

No reason why not.

Buy a couple and put them together. Put it between two pieces of plywood and do the test.

Then you can talk about the results.

P.S.

Andrew,

I dug this up just for you.

Fox large bellcrank. Of which BTW I use two.

Here's their description text.

"Quick Overview

Designed for use with control line models, the

Fox Bellcrank is formed from heavy-duty aluminum alloy sheet. It will stand

a pull test of 50 - 60 lbs., making it suitable for heavier scale models.

The non-binding center pivot will not bind the bellcrank when it is bolted

down tightly. It has three pushrod position holes.

3 3/8" long x 1 5/16" wide."

Of the fairly recent, common commercially available,

ALUMINUM bellcranks, the Fox is probably the best. It's at least made from a harder aluminum. The Veco bellcranks are almost as good as a Fox, but softer, and the Perfect bellcranks are pure crap that belong in the nostalgia box or the garbage can if you can't fight the temptation to actually use one. Well OK, I do have a Perfect bellcrank in my Bi-Slob, but that's a special circumstance where I can see the bellcrank any time I care to look at it, in a plane I fly rarely, and that I didn't expect to last more than a few trips to the flying field. A Perfect bellcrank might be fine for a 1/2A, but then so would a bellcrank cut from decent plywood.

Back when I got my start in the hobby, we used Fox bellcranks almost exclusively. When we started attending contests, I started piling up Perfect bellcranks from raffles. As luck would have it, I happen to have 4 bellcranks laying around to illustrate the problem with aluminum bellcranks. There's a brand new Fox 3" bellcrank, a new Perfect 3" bellcrank, a Fox 3" bellcrank from a box stock Fox 35 powered Flite Streak that survived two seasons, and a Perfect 3" bellcrank from a OS 25FP powered Flite Streak that lasted only a few flights. I will call this set of pictures...

A Tale of Four Bellcranks - An Exercise in Medieval C/L Hardware.

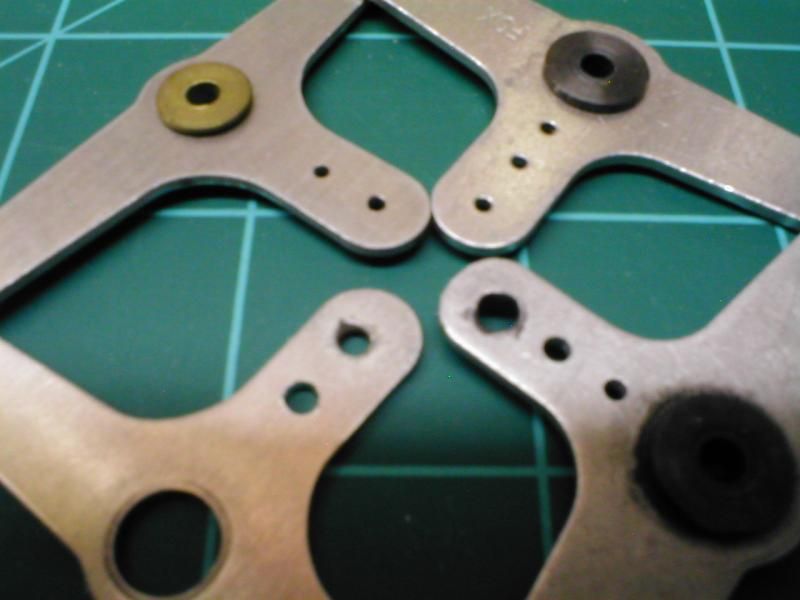

Here we have an establishing shot. The bellcranks in the foreground are used, the bellcranks in the background are new old stock. On the left are products from Perfect, on the right are parts from Fox MFG.

Here we see a close up image of two Fox 3" bellcranks. As you can clearly see, the used Fox bellcrank in the foreground exhibits a dusting of dark powder around the bearing. The powder tests consistent with what you'd find when examining aluminum worn from friction. You can also see the lead out holes are egged out, in the direction of the center of the circle as it would be mounted in the plane. Also, please note that the pushrod hole furthest from the pivot point is egged out from the pushrod wearing against the aluminum bellcrank. It's also worth mentioning that the middle pushrod hole was drilled to fit the .078" pushrod wire when the model was built. The outer hole that was eventually used is approximately twice the size that it was originally drilled when the model was built. In conclusion, a Fox bellcrank used in a traditional manner will wear rapidly.

Here we have a close up image of two Perfect 3" bellcranks. Please note that the brass bushing has popped out of the used bellcrank. Also you will notice that both leadout holes show signs of egging out, and while it's hard to see in the image, the outer pushrod hole is worn oversize. What we can conclude from this image is that a Perfect bellcrank used in a traditional manner will wear rapidly. Keep in mind this bellcrank was only in the model for a few flights.

Images 4, 5, and 6 serve to demonstrate the hole wear between new and used bellcranks of both origin.

Images 7, 8, and 9 display a Fox 3" bellcrank and a Top Flite Flite Streak kit pushrod. The purpose of these images is to demonstrate how dramatically the pushrod wore the bellcrank in a relatively short period of time.

Now about the time I stopped using Fox bellcranks, I started building Sig kits and using their nylon 3" bellcranks. While I regret that I don't have any images of Sig bellcranks available to corroborate my story, they don't wear appreciably, at all when used in a traditional manner. As a general guideline, I still bush the leadouts with tubing through the Sig bellcranks, and I tend to use 4-40 ball links at the pushrod end, but back when I made the switch, I did not take those precautions. In fact the reason I don't have pictures of old used Sig bellcranks, is because I keep reusing them because they hardly ever show any signs of wear. I've got a few that are so old, I'm starting to get concerned about the nylon turning brittle. I get Sig bellcranks from

http://www.mbsmodelsupply.com, 4 for $3.00. List price on a Fox bellcrank is $8 each, and you need two of them?

Not to mention that Fox isn't making engines anymore, so can a person even get a Fox bellcrank? I don't mean to

, I like Fox, but these are also the people that boasted their new ceramic Stunt .60 was so powerful it'd tear the wings off your plane. As if that was a good thing. For old tech, their bellcrank is as good as anyone's, and with the proper precautions they will probably have decent longevity, but there are better options available.