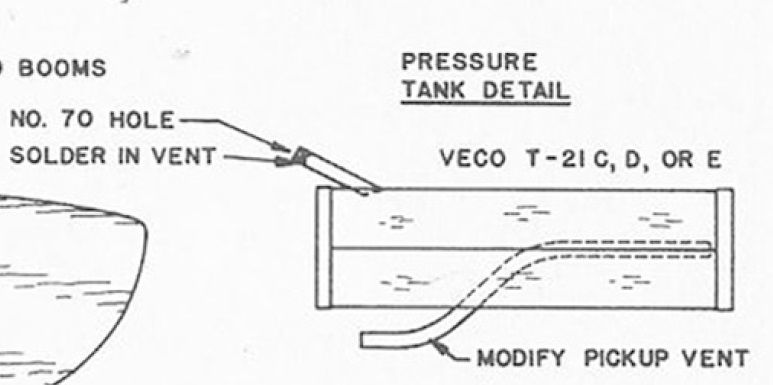

Use a normal 1" tall, 2" wide, by however long (4" or so before you hit the spar) tank. Plumb it so the pick-up tube extends from the normal spot at the right rear of the tank to the front and should exit the bottom of the tank behind and below the leading edge. As mentioned you don't want to compromise the integrity of the leading edge by drilling a hole or cutting a notch for the pick-up tube. The vent is 1/8" tube, and extends just inside the tank on the top. The Voodoo magazine plans show the venting, and also suggest soldering closed the vent and drilling it to size. Another suggestion I was given was to hold a scrap of .018" flying line over a fire until it was blackened with soot, then slip it through the vent or pressure tap and fill the void with solder, before pulling the cable back out. But, I've had good results by just using the stock Fox backplate pressure taps, which have a very small hole from the factory. To fill the tank, hold the plane nose down and fill until fuel streams out the venturi. To start, I generally pinch off the pressure line until the engine fires, but I haven't had any trouble getting the engines started without pinching the line, so I'm not sure it's really necessary.

I have one Voodoo setup with a hard tank as described and backplate pressure (it was miserable on suction) and another running a bladder in a plastic fluorescent light tube. Both are otherwise setup similar, 9x6 APC prop, 10/25 all castor Sig fuel, 57' eyelet-eyelet lines, similar Fox 36X engines. The needle bearing 36X on backplate pressure flies around 100mph, the ball bearing 36X on bladder goes a little faster, both are easy to deal with. The only problem I've had so far was blowing a head gasket on the needle bearing engine. The old combat planes come in handy when the wind doesn't stop blowing for a few weeks, at 100mph the plane couldn't care less about a 20mph wind.